6 Factors to Consider When Selecting Grate Magnets for Business

If you’re considering grate magnets for your business, you’re on the right track. Grate magnets offer an optimised and efficient operation experience while playing a crucial role in various sectors, from food processing to manufacturing.

With various options available, including different magnetic strengths and configurations, making the right choice of grate magnets for your business can be daunting. To aid in this decision-making process, it’s essential to consider several factors carefully, from the material being processed to the specific installation requirements.

Join us as we delve into the fundamental aspects businesses must assess when selecting grate magnets for optimal performance and seamless integration into their operations. By understanding these considerations and their impact on your operations, you can confidently select the grate magnets that best suit your business needs, ensuring long-term success.

What are Grate Magnets?

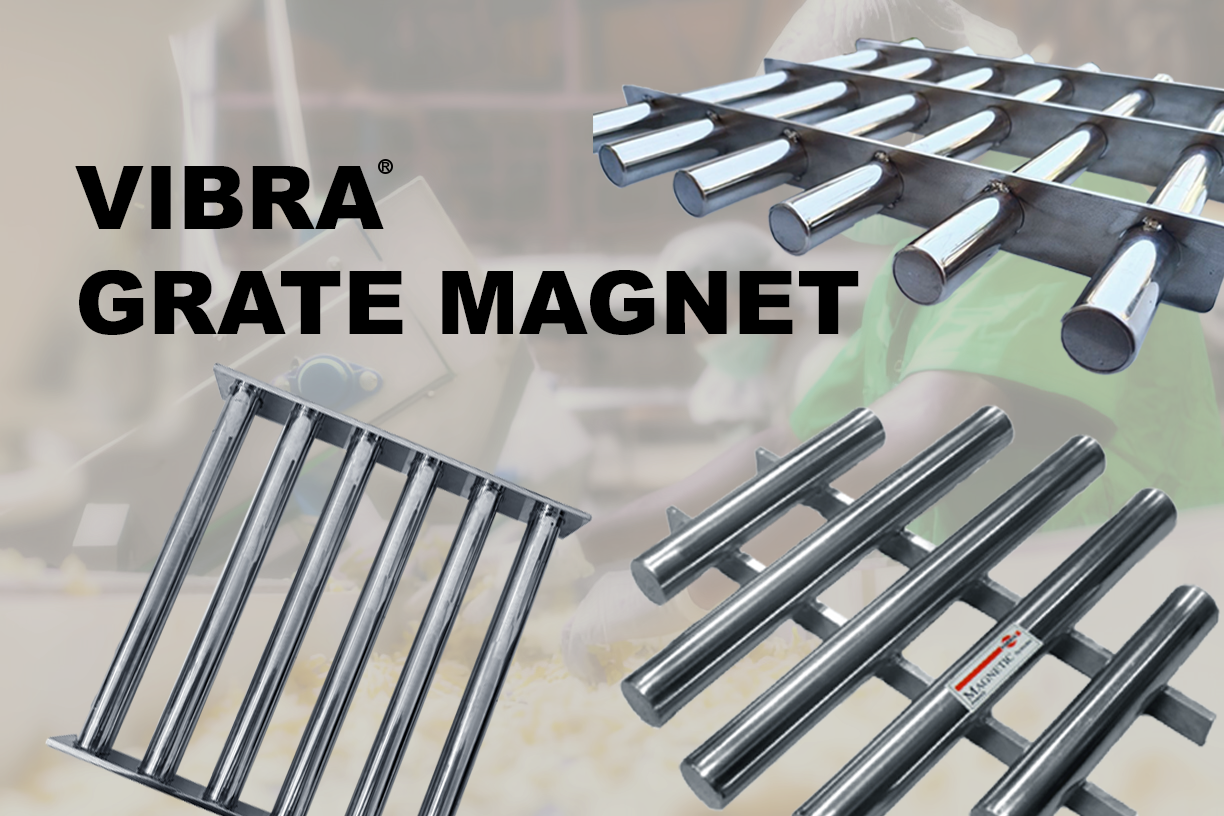

Grate magnets are magnetic separators used in industrial settings to remove ferrous contaminants from dry and free-flowing materials. Consisting of magnetic tubes or rods arranged in a grid-like pattern, these magnets attract and capture unwanted metal particles as the material passes through.

Commonly employed in industries such as food processing, pharmaceuticals, and plastics manufacturing, grate magnets help maintain product purity, prevent equipment damage, and ensure regulatory compliance. They come in various configurations and magnetic strengths to accommodate different applications, offering a versatile solution for businesses seeking efficient metal contamination removal in their production processes.

What to Consider When Selecting Grate Magnets for Business

When selecting grate magnets for business, careful and informed consideration is important. These magnetic separators play a crucial role in maintaining product purity and equipment integrity. Thus, many factors must be evaluated for optimal performance and long-term success in industrial operations.

To help you out in the daunting task of selecting the right grate magnet for your business, here are 6 factors to consider during your selection.

Magnetic Strength and Performance

Magnetic strength is a critical factor when choosing grate magnets for business. Higher magnetic strength ensures efficient capture of ferrous contaminants, enhancing performance and product purity.

Consider the type and size of contaminants present in your process stream, as well as the material’s flow rate. Selecting magnets with the appropriate strength for your application guarantees effective metal separation, minimising the risk of equipment damage and ensuring compliance with industry standards.

Magnet Raw Material

Consider the type and grade of magnet raw material used for the magnet. The choice between new and recycled magnet materials can significantly influence the magnet's overall performance. New magnet raw materials often ensure higher consistency in magnet strength and typically offer longer lifetimes and greater efficiency. In contrast, recycled materials might vary in quality but are a more cost-effective and environmentally friendly option.

Additionally, the grade and type of the magnet material play a pivotal role in determining its efficiency. Different grades and types of magnets will have varied strengths and performance characteristics, affecting the magnet's suitability for specific applications. Thus, businesses must evaluate their specific needs against these factors to choose the most appropriate grate magnets.

Size and Dimensions

When selecting grate magnets for business, size and dimensions are important features to take into consideration. The physical dimensions of the grate magnet must align with the available space in your processing line.

Additionally, the size of the magnetic field is crucial, as it determines the effectiveness of ferrous particle capture. Ensuring the magnet is appropriately sized for your application guarantees efficient metal separation and minimises the risk of clogging or reduced performance.

Regulatory Compliance

Regulatory compliance is a crucial factor in selecting grate magnets for business. It’s important to comply with the current industry standards, especially in industries like food processing and pharmaceuticals.

Verify if the chosen grate magnets meet relevant industry standards and regulations for food safety and product purity. Choosing grate magnets that adhere to these standards guarantees your products’ safety and quality while mitigating the risk of fines or penalties for non-compliance.

Installation Flexibility

Assess whether the grate magnet can be easily installed and integrated into your existing processing equipment, ensuring minimal disruption to operations. You should also consider factors such as mounting options, accessibility for maintenance, and compatibility with surrounding infrastructure, which helps to see the installation flexibility of the grate magnets.

Opting for magnets that offer versatility in installation allows for seamless integration into diverse production environments, enhancing operational efficiency and minimising downtime for maintenance or reconfiguration.

Cleaning and Maintenance Requirements

Cleaning and maintenance requirements should also be considered when selecting grate magnets for business. Choosing a grate magnet that requires extensive maintenance might significantly impact your operation and production process.

Instead, opt for magnets with easy-to-clean designs to minimise downtime and labour costs. Features such as quick-release mechanisms or self-cleaning options can streamline maintenance tasks.

Additionally, assess the frequency of cleaning needed based on your production volume and material characteristics. By choosing magnets that facilitate efficient cleaning processes, you can ensure consistent performance and prolong the lifespan of your equipment, enhancing overall operational efficiency.

Where can you get grate magnets in Malaysia?

If you’re looking for grate magnets in Malaysia, look no further than Sematic Magnet. With a wide range of high-quality magnets designed for various applications and specifications, trust us to provide quality products with our expertise to make your projects successful.

Experience an optimised and efficient operation and production process with grate magnets.

Contact us today to learn more about what you need, and our experts will help you choose the ideal magnet solution for your problem.